Marking & Cutting Specialists

Services

We offer a long range of services to suit what you need. Check out more details about our services on our services pages.

Laser Engraving

Discover the precision and versatility of our laser engraving and marking services, tailored to enhance a wide range of materials and products with intricate designs and lasting impressions.

Rotary Engraving

Discover our range of rotary engraving services, tailored to meet your every need with precision and care. We offer engraving on a range of products including awards, parts, personalised gifts and more.

Explore Our Product Range

At LaserMarking, we specialize in creating custom solutions tailored to your needs. From personalised gifts to industrial labels, our products are designed with precision and quality in mind.

Custom Products

Our custom products are crafted to meet your unique specifications. Whether you need bespoke signage or personalised name badges, we deliver exceptional results every time.

Labels & Signage

Enhance your brand visibility with our durable labels and eye-catching signage. Perfect for businesses looking to make a lasting impression.

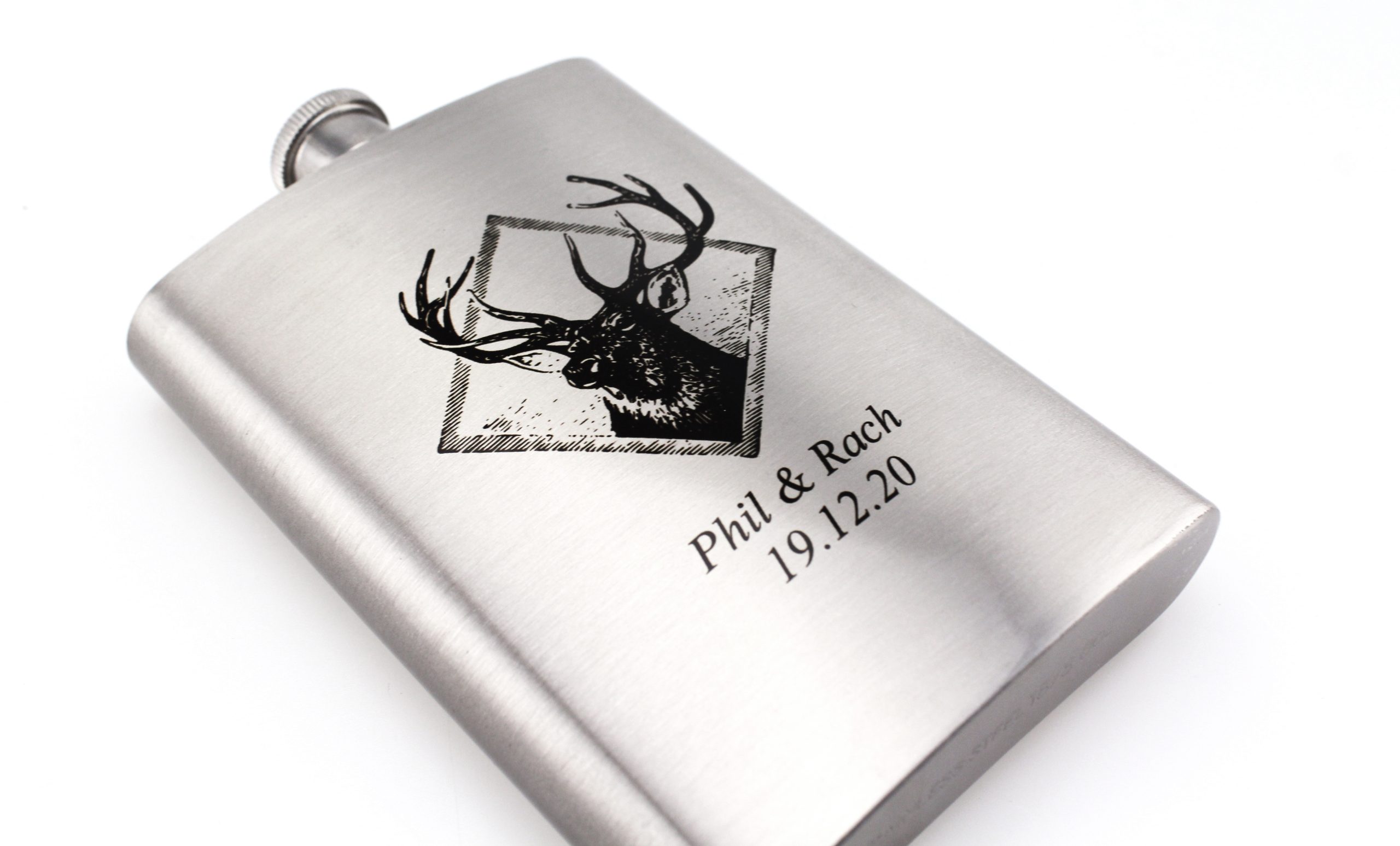

Giftware & Weddings

Celebrate special moments with our exquisite giftware and wedding accessories. From elegant cake toppers to personalised gifts, we add a touch of elegance to your occasions.

Our Locations

EAST TAMAKI - AUCKLAND

LaserMarking Ltd

29G Sir William Ave, East Tamaki

Auckland

P: 09 272 4300

info@lasermarking.co.nz

Mon – Fri | 8:00am – 4:30pm

Or send us a Message...

NORTH SHORE - AUCKLAND

LaserMarking Ltd

Shop 4-6, 47 William Souter Street,

Forrest Hill, Auckland 0620

P: 09 410 4715

apex@lasermarking.co.nz

Mon – Fri | 8:30am – 5:00pm

Or send us a Message...

Nationwide Service Available

At LaserMarking, we are proud to offer our engraving solutions beyond our Auckland locations. Whether you’re in the North Island or the South Island, our comprehensive services are available to meet your needs. We ensure that every project, no matter where you are in New Zealand, receives the same level of precision and quality that our Auckland customers enjoy. Experience the convenience of nationwide service with LaserMarking today.